This week Aerojet Rocketdyne announced it has completed its Commercial Crew Integrated Capability (CCiCap) commitment in support of Boeing’s Crew Space Transportation (CST-100) “space taxi,” one of three low-Earth orbit (LEO) spacecraft being developed with NASA funds, and competing for a NASA contract, to return LEO human spaceflight capability to the United States by 2017.

Since the retirement of NASA’s space shuttle fleet in 2011, the U.S. has been forced to buy seats for our astronauts to fly to and from the $100 billion International Space Station (ISS) from the Russians, on their Soyuz spacecraft, at a cost of over $70 million per seat. The CST-100 is Boeing’s answer at ending our nation’s dependence of Russia for crewed LEO transportation, and the work Aerojet Rocketdyne has done with Boeing on CST-100 since 2010 has continued the development of the CST-100’s service module and launch abort propulsion system, and will help return astronauts to LEO from U.S. soil soon.

“Over the past year, we’ve achieved major milestones that are paving the way for CST-100 to take flight,” said Terry Lorier, Aerojet Rocketdyne’s CST-100 service module propulsion system program manager. “In total, during the CCiCap contract period of performance, Aerojet Rocketdyne conducted eight Launch Abort Engine (LAE), 49 Orbital Maneuvering and Attitude Control (OMAC) system and 33 Reaction Control System (RCS) hot fire tests, all of which helped mature the system design to position Aerojet Rocketdyne to be ready to move into qualification testing early in the next phase of the program.”

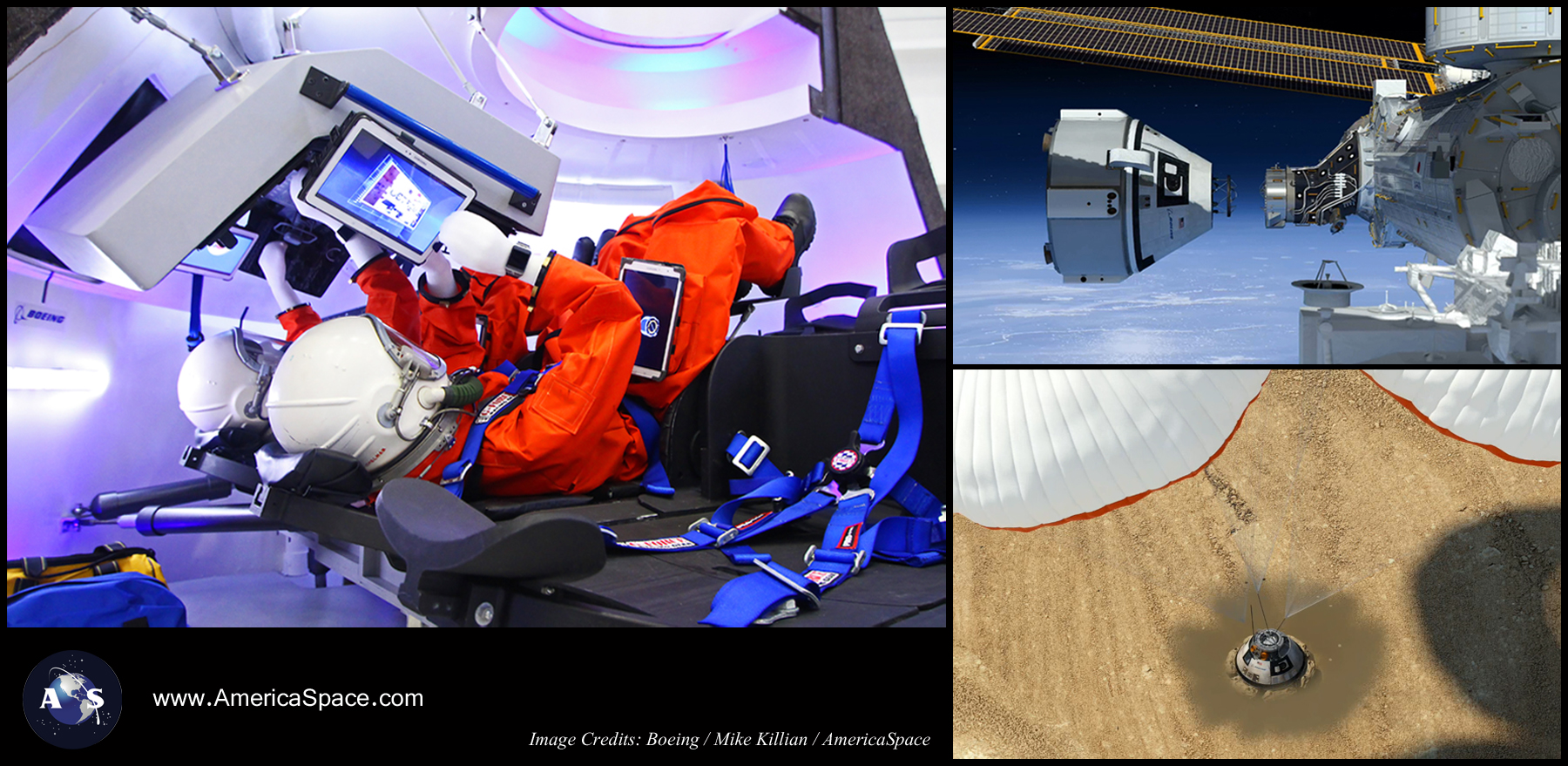

Boeing’s capsule-shaped CST-100 is designed to take up to seven people, or a combination of people and cargo, to LEO and the ISS. Its service module and integrated launch abort propulsion system are designed to “push” the crew capsule to safety if an abort becomes necessary during the launch or ascent. If an abort is not necessary, which hopefully will always be the case, the propellant and propulsion system could instead be used to re-boost the orbit of the ISS, or be used to complete the spacecraft’s nominal mission through separation of the crew module from the service module as it begins re-entry back into the Earth’s atmosphere.

“The LAE test series saw the engine successfully operate at twice its mission life, producing 39,700 pounds force thrust,” said Lorier. “The four LAEs are derived from proven hardware based on heritage designs.”

The CST-100’s service module propulsion system will be powered by 24 1,500-pound thrust class OMAC engines, which are positioned in four clusters of six on the service module. They will provide low-altitude launch abort attitude control, maneuvering, and stage separation functions, high-altitude direct abort capability, and help the CST-100 to refine its orbit and “brake” at the end of a mission to slow down for re-entry.

The OMAC tests Aerojet carried out for Boeing’s CST-100 verified their durability in extreme heat, evaluated the opening and closing of their valves, and confirmed continuous combustion and performance. The thrusters were outfitted with numerous instruments and were fired in a vacuum chamber that simulated the space-like environment at an altitude of 100,000 feet, giving engineers a chance to evaluate the thrusters through the burns and stresses they would encounter during a real flight.

“Boeing’s unique service-module propulsion system combines on-orbit propulsion with ascent abort capability into a single system, allowing the OMAC engine and the majority of the propellant feed and pressurization hardware to perform dual roles,” said John Mulholland, Boeing vice president and program manager, Commercial Programs. “This dual-role feature reduces the number of parts and provides operational flexibility, increasing system reliability and improving crew safety.”

According to Aerojet, the 28 100-pound thrust class RCS engines are adapted from a similar engine design currently in production. These engines provide high-altitude abort attitude control, on-orbit low delta-v maneuvering functions, and space station re-boost capability.

Boeing must pass two reviews coming up later this summer before completing their CCiCap agreement with NASA. A full critical design review (CDR) will examine the detailed plans for the spacecraft, launch vehicle, and a host of ground support, processing, and operations designs. The second review will come soon after, the Spacecraft Safety Review, which is meant to show the design of the CST-100 and its systems are in line with Boeing’s CDR-level design.

NASA is expected to announce which of the three companies it has funded to participate in CCiCap (Boeing, SpaceX, and Sierra Nevada) will advance to the next round of spacecraft development, known as Commercial Crew Transportation Capability (CCtCap), as soon as the end of this summer. If NASA selects Boeing to continue with CST-100 development, then the company would immediately move their operations to the Kennedy Space Center to manufacture, assemble, and test the actual CST-100 flight article.

Boeing, in partnership with Space Florida, is already leasing the former space shuttle Orbiter Processing Facility Bay-3 to do this, modernizing the facility (now known as the Commercial Crew and Cargo Processing Facility, or C3PF) to provide an environment for efficient production, testing, and operations for the CST-100 similar to Boeing’s satellite, space launch vehicle, and commercial airplane production programs.

Since 2010 NASA has given $1.5 billion to foster the development of a commercial crew spaceflight capability, and between the three companies competing for the ultimate contract Boeing has received the biggest chunk of change ($600 million so far). The space agency has expressed its wishes to award commercial crew contracts to at least two companies, but that will be dependent on whether or not Congress provides adequate funding.

NASA is expected to announce the winners of their Commercial Crew Program by September, which will pave the way to the final lap toward launching U.S. astronauts from American soil once more by 2017.

Want to keep up-to-date with all things space? Be sure to “Like” AmericaSpace on Facebook and follow us on Twitter: @AmericaSpace